THERMICFLUID HEATERS

THERMIC FLUID HEATERS are heating equipment used in industries where heat transfers are the primary need of the process instead of Steam pressure.

An industrial heating system that transfers heat from one medium to another uses thermal fluid as the heat transfer medium. It is ideal for processes where the temperature requirement is as high as 300 degrees C.

They are typically used in applications where high temperatures and low pressures are required,

Advantages:

The advantages of using a thermic fluid heater include

- Precise temperature control

- Uniform heating

- Versatility in fuel options

- The ability to operate at high temperatures without the risk of pressurization like steam systems.

They are commonly used in processes such as heating reactors, dryers, heat exchanges, and various types of industrial equipment where precise and efficient heating is required.

Thermtech Systems’ Thermic Fluid Heaters are engineered for precision heating with high efficiency and safety. Designed to handle temperatures up to 300°C or more without the need for high-pressure systems, these heaters provide reliable performance for a variety of industrial applications.

These heaters are commonly used in various industries, such as

Our products are used in various industries, such as

- Rice Mill Industries

- Pharma & Bulk Drugs Industries

- Chemical Industries

- Textile Industries

- Packaging Industries

- Food & Beverages

- Animal Feed Industries

- Tyres Industries

- Aromatic & Solvent Extraction

- Rubber Reclaim Industries

- Automobiles Industries

- Oil Refinery & Petrochemical

- Fertilizer Industries

- Paper Industries

- Distillery Plants

- Common Effluent Treatment Plant

THREE PASS OIL/GAS FIRED THERMICFLUID HEATERS -FFT SERIES

- Range: 50000 to 3000000 kcal/hr

- Fuel: HSD, CNG, LPG, FO, Biodiesel, pellet

SPECIAL FEATURES

- Three pass Design

- Horizontal /Vertical design

- Less fuel consumption

- Higher efficiency 70% to 80 %

- Less external exposed heating surface to reduce heat loss

The thermic fluid heater is a packaged, fully automatic, HSD/CNG/LPG fuel-fired liquid phase heater.

It comprises a double-helical heat exchange coil, which forms the combustion chamber and provides the heating surface in an optimally designed configuration.

The coil is enclosed in an outer shell. The outer shell is then Insulated with a ceramic blanket and clad with a GI-colored sheet to conserve radiation heat loss from the surface and keep the outer cover near ambient temperature.

It comes on a skid mounted in ready-to-use condition. It has a thermic fluid circulating pump with a motor, a fully automatic imported burner, a de-aerator, and expansion vessels with nitrogen blankets that are provisioned to operate at maximum temperature, along with all control panels and safety features.

Thermtech Systems’ Three-Pass Oil/Gas-Fired Thermic Fluid Heaters are designed to deliver superior thermal efficiency and consistent performance, making them an ideal choice for industries requiring high-temperature heating solutions.

Solid Fuel-Fired Conventional-Type Thermic Fluid Heater

Capacity: 50000 to 3000000 kcal/hr

Fuel: Wood, Briqquetts, Biomass, Coal

Skid-mounted type thermic fluid heaters are designed to be quickly erected and commissioned in less time.

Conventional thermic fluid heaters are designed to maximize the heat transfer area for maximum efficiency, reducing the boiler room construction cost and area and the refractory cost.

The convective coil Pressure parts are fabricated from high-temperature-resistant carbon steel tubes Bs 3059. Two conductive helical coils are mounted directly over the furnace for maximum radiation heat absorption.

The coil is housed in a shell fabricated from M.S. Plates (IS 2062 Gr. A/B), and a top and bottom shell refractory is done.

Cyclones-air furnaces are designed like pellet burners with fuel flexibility to minimize fuel unburnt percentage, less excess air, and increase refractory life.

The furnace has a fire door assembly with graded CI fire bars and proper air gaps for efficient combustion. Using a multifuel fire bar, we can use all kinds of fuels, such as wood, solid coal, and husk.

Air preheater cum cyclone filter has a shell & tube type heat exchanger, which preheats combustion air by flue gas coming from Coil assembly & thus increases efficiency by 4-5%; Cyclone type Dust collector, which ensures ash collection from flue gas.

The expansion tank is sized for thermal accommodation expansion of the thermic fluid in the system, and the gasser vessel is uniquely designed for de-aerating the heating media and removing low boilvapors. It has a level indicator, nozzles for overflow, a drain vent, and a magnetic float switch.

Electrical control panel: Dust-protected, Powder coated, prewired electric & control panel with necessary contactors, control switches, and safeties

Electrical Heating Thermic Fluid Heaters

Range : 20000 to 600000 kcal/hr

SPECIAL FEATURES

- Fully automatic

- Low maintenance.

- Easy to install and can be located close to the point of use.

- Environmentally friendly and pollution-free.

- Less floor space.

- Efficiency 70% to 80 %

A thermic fluid heater is a packaged, fully automatic, liquid-phase heater.

It comprises a thermic fluid storage shell within a direct ceramic electric heater. Ceramic heaters mounted in the MS pipe. The pipe is in direct contact with thermic fluid oil. Thermic fluid circulating pipe is then further insulated with an insulation blanket and clad with a coloured sheet to conserve radiation heat loss from the surface and keep the external shell near ambient temperature.

Cast steel centrifugal air-cooled thermic fluid circulating pumps are duly coupled with a motor and mounted on a base frame.

The expansion tank is sized for thermal accommodation expansion of the thermic fluid in the system, and the gasser vessel is uniquely designed for de-aerating the heating media and removing low boilvapours. It has a level indicator, nozzles for overflow, a drain vent, and a magnetic float switch.

THERMIC FLUID HEATING STEAM BOILERS

Thermal Oil-Heated Steam Boilers These are custom-built media-heated steam boilers, ideally suited to utilize the spare heating capacity of existing thermal oil heaters to supply or augment plant steam.

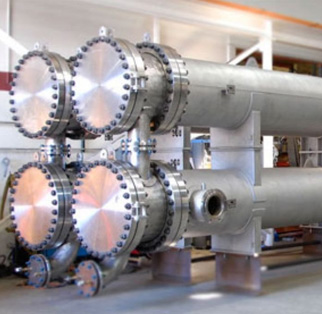

Being un-fired pressure vessels, these are silent stationary boilers, easy to operate & maintain. Essentially, these are horizontal shell & tube-type heat exchangers built to SIB or Class 1 IBR steam boiler codes, with the addition of a feed water pump, three-way thermal oil pneumatic valve & related controls used in shell boilers.

Due to the ample boiling water & steam storage capacity of the shell, steady dry steam generation is achieved. These are made as factory-assembled packaged boilers, ready to install & operate with minimum effort. RTS steam boilers are easy to maintain and operate, as fuel-burning hassles are absent.